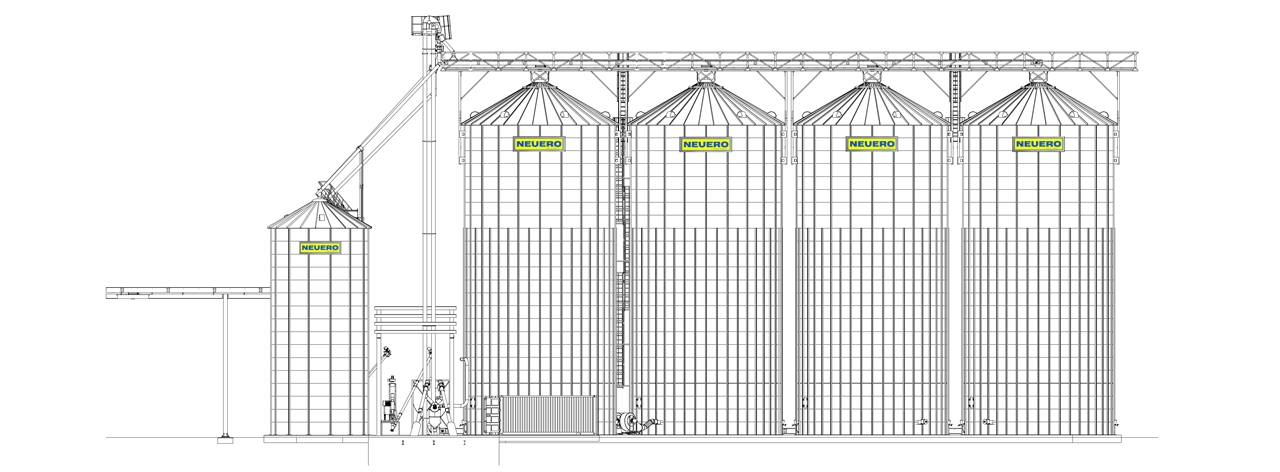

Warum NEUERO

Wer tagtäglich mit seinen Kunden redet, und das tun unsere Berater in landwirtschaftlichen oder industriellen Betrieben in nahezu jedem Winkel der Welt, der kennt bald nicht nur jedes Problem, er hat auch für alles und jedes passende Lösungen